OncQue slotted photoelectric sensors

|

|

|

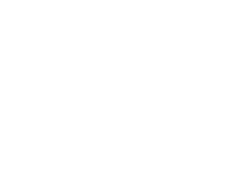

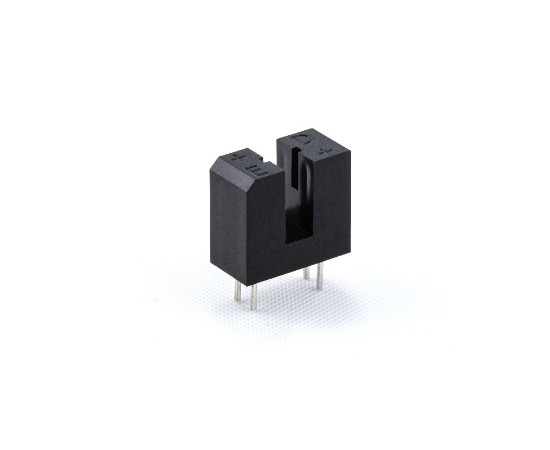

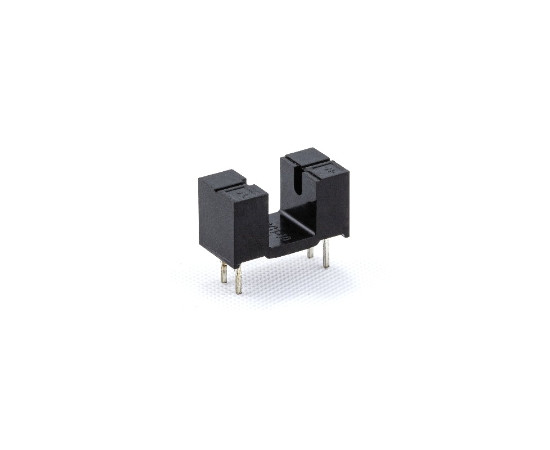

OncQue slotted photoelectric sensors Light radiation is increasingly used for the detection of objects, their movements and position in various types of automatic systems. The fact, that the measurements are carried out touchless, significantly increases the lifespan of light-based machines and reduces the amount of needed maintenance. Therefore it is worth reaching for optical sensors if they are a possible option. Transmissive Photo Interrupters are elements that work like light barriers, they characterize with a very small operating zone. Usually, the area in which they are able to detect objects is limited to a few centimeters (max). However, this limitation leads to many advantages - the gap sensors are not only small, but also very precise and easy to install without any errors. PRINCIPLE OF OPERATION Photoelectric sensors work in a very simple way. They consist of two elements, which in the case of transmissive photo interrupters are placed in one compact housing (a cuboid with a cutout). There is a transmitter at one end of the slot and a receiver at the other end. The transmitter is a LED diode - usually working in infrared- sometimes having the parameters of a laser diode. The receiver is, for example, a photo transistor. Infrared makes the sensor insensitive to interference caused by light in the visible range. When an object, that blocks the passage of the light beam, passes through the sensor aperture, it is detected on the receiver side which causes difference in the electrical signal at the sensor output. The dense design of the slot sensors makes their installation really easy. There is no fear that the movement of objects in their vicinity as well as vibrations and other shakiness (transmitter and receiver displacement -relative to each other) will cause the a damage of the detector. High reliability of this type of systems and very fast work allow them to be used in very demanding applications, especially for the detection of fast-moving, thin objects. ONCQUE SENSORS A good example of slit photoelectric sensors are products of the Taiwanese company OncQue, also known as Bravotronics Corporation. Thanks to the highest quality and innovative solutions, OncQue products have been appreciated by customers for years, as evidenced by many industry awards. The company's credibility is confirmed by the implementation of quality assurance systems: ISO9001: 2000 - since 2006, ISO9001: 2008 - since 2009, as well as ISO14001: 2004, ISO45001: 2007. Currently, OncQue has over 150 patents. OncQue has over 20 years of experience and specializes in various types of sensors, including a fairly wide selection of gap sensors. They are made in a casing of high-quality plastic, resistant to high tensions, so that they do not fracture during the installation. In addition, pins for through-hole technology (THT), assembly increase the strength of the connections. They consist of four pins: anode, cathode, collector and emitter. The anode and cathode power the LED in the transmitter, and the collector and emitter allows to read the state. The OncQue sensors are powered by 5 VDC and consume 10 mA by default. To connect them, a 390 Ω resistor should be inserted in series, and a 33 kΩ resistor in the output circuit. Do not exceed 30 mA at the input and 20 mA at the output. The total power consumed by the sensor shall not exceed 75 mW. The permissible operating temperatures range is from –25 ° C to + 85 ° C, and the storage temperature in the warehouse must be between –40 ° C and + 100 ° C. This means that you can freely stock up on a supply of these inexpensive components (and use them, if they become suddenly necessary) without fear of damaging them during storage. Is worth to know that during soldering, the element temperature should not exceed 260 ° C for no longer than 5 seconds. The time of rising and falling of the signal on the detector -which determines the maximum speed of object detection- is also important. Typically this value is 20 μs when a 1 kΩ resistor is used in the load circuit. This means that just a little over 40 μs is enough to detect the appearance and disappearance of an object, as long as the sensor's control circuits are sufficiently fast. AVAILABLE MODELS Transmissive photo interrupters are produced in many variants, differing in dimensions, and above all in the size of the slot and the active area. For OncQue, the gap can be from 3.1mm to 15mm. Additionally, it is worth to pay attention to the mounting holes, which the sensor can be equipped with and which may be on the left, right or on both sides of the sensor. They allow to increase the reliability of the installation. The list of available models that can be purchased from the Polish OncQue distributor, Micros, is presented in Table 1. EXAMPLES OF APLICATIONS Transmissive photo interrupters are great for detecting the presence of fast-moving objects, especially thin ones. As a result, they can be used, for example, to monitor the presence of paper or other tapes. Rapid operation allows them to detect the continuity of any object. It doesn't matter if these objects are magnetic, metallic, rough, shiny, or even what temperature they have. The most popular applications include monitoring the presence of paper in printers and on production lines. The sensors work well as elements of various safety systems, counting systems or specific optical encoders. They are also used in building automation. In practice, it also turns out that many industrial processes can be slightly modified so as to force a small, stiff element to be moved through the photoelectric sensor gap, which will allow detecting for example the position of the actuators. The use of more than one detector, on the other hand, will make it possible to measure the speed of objects traveling the distance between two sensors. Transmissive photo interrupters are so universal that their use largely depends on the creativity of engineers who use them. Additional application ideas can be obtained by consulting with professionals who have seen such sensors in many applications. It is worth contacting application engineers from Micros who will be happy to help with the use of these and other sensors in industrial applications. Source: "Automatyka Podzespoły Aplikacje" 2020/01, p. 66-67. |

|

| We invite you to familiarize yourself with the full offer of PHOTOELECTRIC SENSORS: CLICK HERE | |