Relays offered by Micros

|

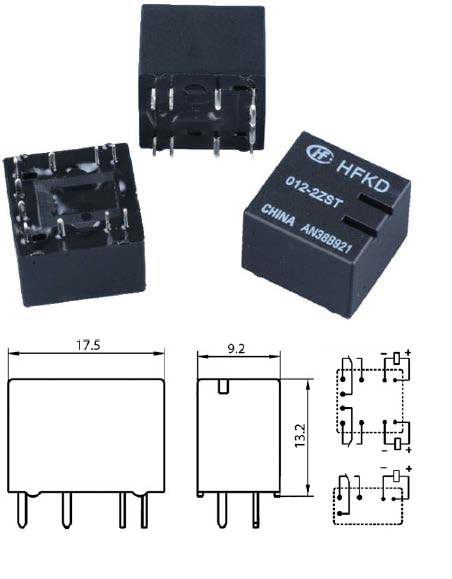

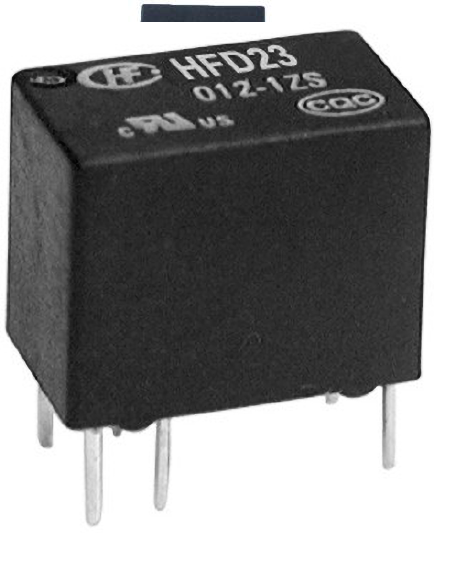

Electromagnetics relays are one of the oldest electronic components. Due to their ability to pass high power signals (both high voltage and high current), robustness against power surges and, galvanic separation of controlling circuit. Makes them difficult to replace with alternative components. In the Micros’s offer you can find wide range of Hongfa’s relays. They are available in varied configurations of contacts, voltage and current versions. These relays are mostly specialized and directed to specifics tasks. Power relaysHF3FF relays are miniature power relays with dimensions of 19×15,5×15 mm. intended for PCB montage (photo 1.). There are available two versions – switching relays and contact relays, both with high current capacity (up to 15 A with 277 VAC and 30 VDC). The insulation between coil and contacts is rated to maximum of 1,5 kV. Maximum power dissipation by coil reaches up to 360 mW for versions controlled by 5, 9, 12 i 24 VDC. The operating temperature range is from –40 to +70°C. Thanks to AgSnO2 contact plating, they are able to withstand high inrush currents. They are rated up to 10 mln cycles. HF32F relays are also a miniature power relays with dimensions of 18,5×10×15,5 mm intended for PCB montage (photo 2.). They mostly come in contact version (current capacity 5...10 A, with 250 VAC and 30 VDC). Switching versions have lower current capacity up to 3 A with this same voltage. Characteristic feature of this model is improved insulation between coil and contacts (2.5 kV). Power absorbed by coil nominally reaches up to 450 mW, but versions with higher sensitivity range (Sensitive) work with 200 mW at 5, 9, 12 i 24 VDC. The operating temperature range is from –40 to +70°C. Most frequent among them are versions vith AgNi contact plating, which is proven coating material. The relatively low nickel content (10%) serves as mechanical hardening of silver and provides resistance to erosion of contact areas (they become more durable at higher loads). It is an ideal solution for resistive loads, applications operating at full nominal power and for other types of loads where the inrush current is not so high. Advantages like low cost and good overall characteristics , make this material good choice for many power relays. HF46F relays are miniature power relays with characteristic dimensions of 20,5×7×15,5 mm, intended for PCB montage (photo 3.). They are available in only contact version (current capacity up to 5...10 A, with 250 VAC and 30 VDC). Besides the shape of the housing, they stand out in increased insulation between coil and contacts (they are rated from 4kV to 10 kV for surge type voltage spikes). Power dissipation by coil reaches up to 200 mW (with 5, 9, 12 and 24 VDC). There are available versions with AgNi and AgSnO2 contacts plating. Extended operating temperature range reaches from -40 to +85°C. Unique small weight (about 3 g) ad tiny dimensions in PCB board allow for unusual use. Some applications need relays with even higher durability. Systems that perform fast charging or control high-power motors must be able to connect high currents, and this cannot always be achieved with semiconductor components. This is the reason why HF1105F were created. They are high power elements within housing dimensions of 32×27×20 mm, intended for PCB montage (photo 4.). HF1105F come in three versions: contact, break contact or switching contact. All of them are rated for high load capacity up to 40 A ( 277 VAC and 28 VDC). Insulation between coil and contacts is rated for 2,5 kV or 4 kV (it depends on the version). Power dissipated by coil reaches up to 900 mW (for versions controlled by 5, 9, 12 i 24 VDC). You can also find models with alternating current (AC) as an input (typically-12, 24, 220 VAC). Operating temperature range reaches from -55 to +85°C. Due to AgSnO2 contact plating they have high durability and are able to withstand big inrush currents. One of the most popular relays are these from HF115F series. Dozens of different models are available for universal and specialized applications, as well as many accessories such as relay sockets. HF115F are miniature power relays with dimensions of 29×13×16 mm, intended for PCB montage (photo 5.). They come in configurations (switching relays and contact relays). Nominal power from 8 to 16 A (with 440 VAC and even 300 VDC). The insulation between coil and contacts is between 2 and 4 kV. Power dissipated by coil reaches up to 400 mW (in 5, 9, 12 i 24 VDC versions). Operating temperature range: –40 to +85°C. Contact plating mainly consist of AgSnO2. Another Hongfa’s relay is the HF118F model for high-power control circuits (photo 6.). They are also available in, switching and contact versions (current capacity of this particullar one is 10 A at 250 VAC.). With load capacity like this, power demands by coil are small- only 220...290 mW (it depends on rated voltage). Relay works in –40°C to +85°C temperature range. HF118F has small dimensions (28,5×10×12,5 mm) compared to his mass (8 g). Electric insulation of 5 kV between the contacts and the control side achived with 8-mm insulation gap. Because of this this relay meets the VDE 0700 and 0631 standards for insulation quality. Relays in motorizationOne of the more special type of relays are Automotive relays. Their design, and especially the contact, are optimized to work with direct voltages; 14 ... 28V. Typical models are HFKx series relays, for example HFKW or HFKD (photos 7. and 8.). Although their high permissible load currents(20 ... 40 A) they are closed in compact housings (photo 5.-relays of the HF115F series). HF118F series relays, for example HFKW have the dimensions of 16 × 15.5 × 14 mm, and HFKD; have dimensions of 17.5 × 9 × 13 mm. The power consumption of the coil is approx. 600 mW and the control voltages are mainly 12 and 24 V. Some models are available in a double version containing two sets of contacts and control coils (photo 8). They are intended, for example, to control bidirectional DC motors Signal relaysRelays are usually associated with actuating circuits because they enable the control of high loads with the low power required to drive the electromagnet coil. However, the design of the relays gives them another very important feature - galvanic separation of the control and controlled circuits. Such a feature may be crucial for measuring or medical technologies. On the one hand, it ensures that we do not influence the switched circuit in any way, and on the other hand, we meet safety standards. Typical "signal" relays, also referred to as "telecommunication" relays, are the HFD23 and HFD27 type relays (photos 9 and 10). These are components with small dimensions, adapted to switching small loads, max. 2 A. The switching power of the coil is about 200 mW. There are versions with increased sensitivity. In those relays power draw is reduced to 150 mW. The rated voltage of the coil can be from 1.5 to 48 V. An important design feature of signal relays is AgNi + Au coating. Which means that it is an additionally gold-plated silver-based contact. This solution guarantees safe and reliable operation of the element. When selecting the signal relay, it is necessary to pay attention to the minimum contact load. For HFD23 it is 1 mA at 5 V, while for HFD27 \ values of 10 mA and a voltage of 10 mV have been achieved, which allows it to be used in the tracks of measuring devices Source: "Elektronika Praktyczna" 2020/09, p. 84-85. |

Photo 1. HF3FF series relays Photo 2. HF32F series relays

Photo 3. HF46F series relays Photo 4. HF105F series relays Photo 5. HF115F series relays Photo 6. HF118F series relays Photo 7. HFKW series relays Photo 8. HFKD series relays with a description of the leads Photo 9. HFD23 series relays Photo 10.HFD27 series relays |

| We invite you to get acquainted with the full offer of the RELAYS: CLICK HERE | |